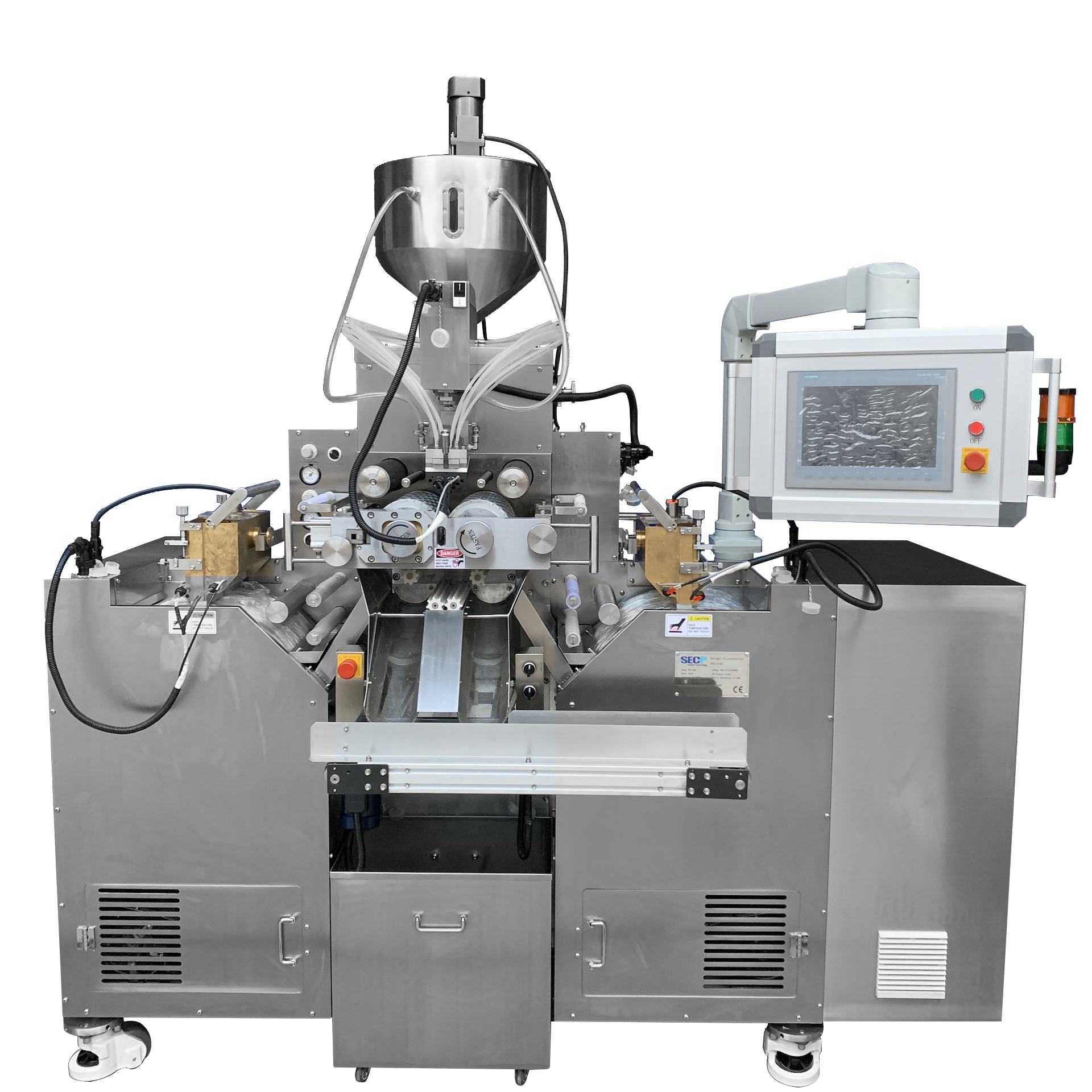

Big Production SEC-106 Softgel Machine

Large production type SEC-106 softgel encapsulation machine, large capacity, most popular by middle and large scale softgel manufacturer. Available for gelatin, vegetable hydroxypropyl starch, sodium alginate. Good for medicine, supplement, paintball and cosmetic skin care softgel production. Good for suspension, paste, high viscosity, PEG fill, lecithin fill, hard encapsulation fill content.

MTBF Time: Around 10 years

Features and Parameters

- Die Roll variable frequency rotary speed: 1-5RPM

- Main machine dimension: 2050 x 1200 x 1850 mm

- Weight: 1900kg

- Power: 11Kw

- Piston quantities: 24 tubes piston

- Single piston fill volume: 0-1.5ml

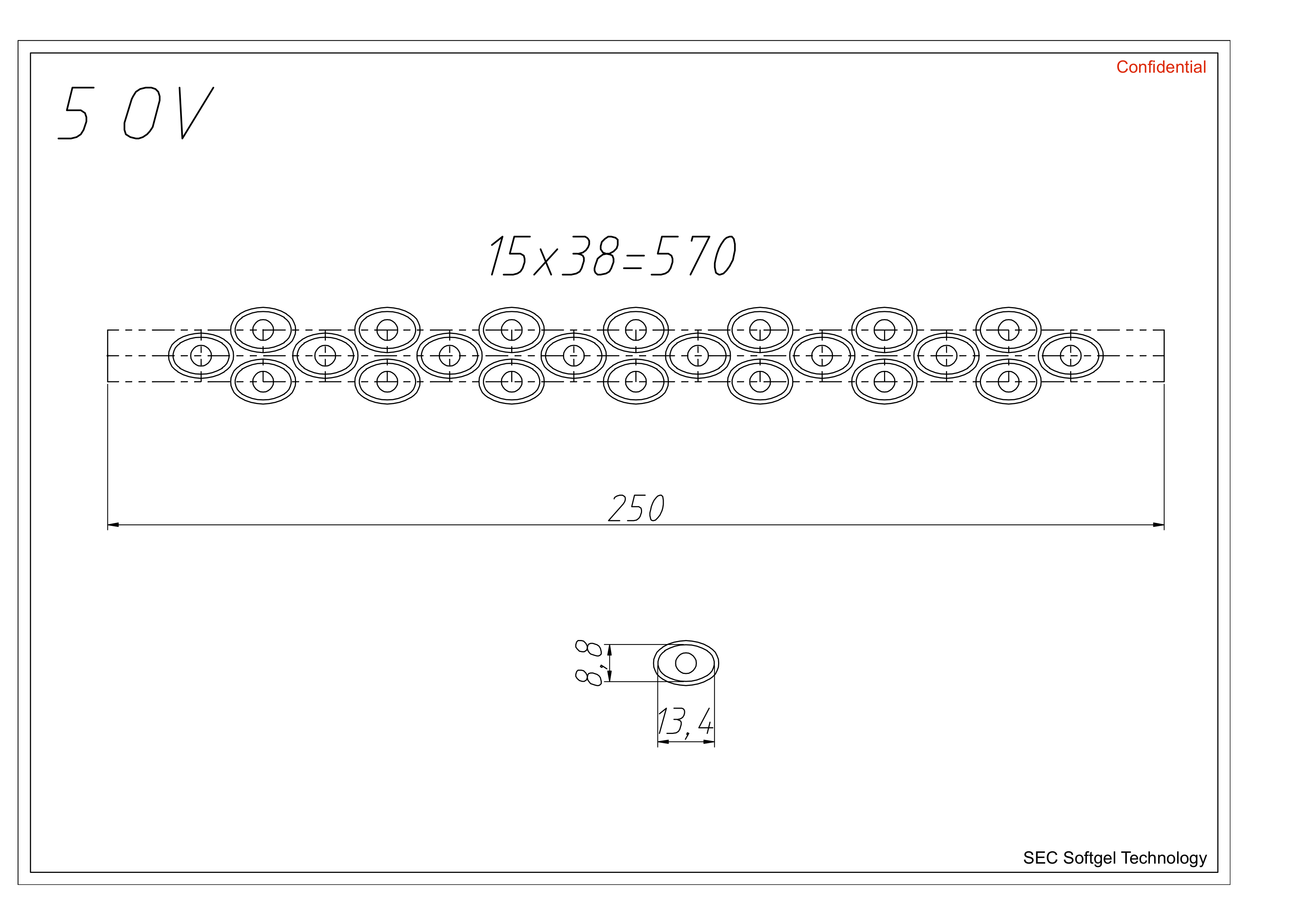

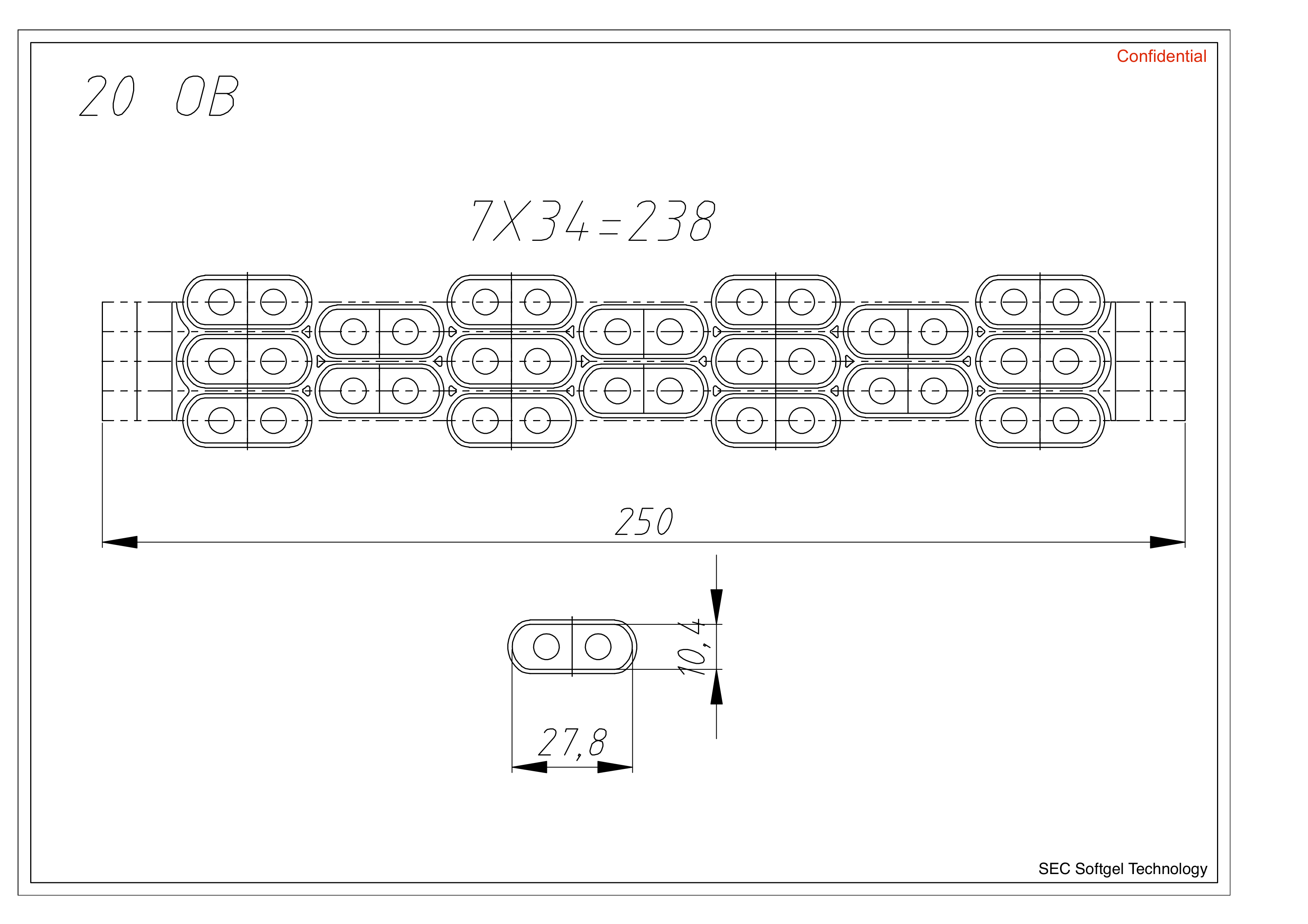

- Die roll specification: Φ150×250mm

- Super micro lubrication system, soft capsule free of cleaning

- Insulation hopper, with stirring, suitable for various types of material

- Die roll set air blowing system, soft capsule shaping more beautiful

- SMC air pressure system, highly reliable

- Voltage: 380V, 50Hz / 220V 60Hz

- Equipped with patent constant temperature injection wedge, electric heating type, temperature increasing fast, balanced and stable.

- Equipped with patent spreader box, comparing with same model, it can increase output 6%-15%, save gelatin liquid material 3%-10%.

- Gelatin ribbon utilization rate % :

- 20 Oblong, 70.8% when cavity number 7x34=238

- Gelatin ribbon cooling by water cooling, making the cooling more even and effective, helping the stable and better encapsulated soft capsules.

- Output:

Around 136,800 capsules/hour for 5 Oval at 4RPM with normal oil fill.

Around 57,120 capsules/hour for 20 Oblong at 4RPM with normal oil fill.

Welcome to contact our professional sales engineer for further support at sec@secsoftgel.com

- Equipped with patent material fill pump. Its design reduced friction, extend service life of material fill pump, reduced phenomenon happen of softgel fill content too sticky lead by overheating of heat that generated from friction, increased product quality, the reduction of friction, it can increase rotary speed of main machine, increased output.

- Patent machine head mold base mechanism, higher precision, average no malfunction time longer.

- High precision, digital, online control micro gelatin ribbon lubrication system, it can memory and store and optimum lubrication oil amount value, adjusting more convenient, accurate, softgel cleaning-free, shorten drying time and increase production efficiency.

- Adopt independent water cooling machine to have gelatin ribbon wheel temperature controlling, more stable, more convenient of operation.

- Equipped with own patent gelatin box, gelatin liquid level is controlled by capacitive proximity switch, no touch, stable and reliable. Reducing wastage of gelatin ribbon, it saves gelatin liquid material 3%-10%; more cavity numbers, it increases output 7%-15%.

- Light conveyor, small volume, light weight, convenient to disassemble and assemble, convenient for cleaning.

- Operation interface design more human friendly, simple direct view, easy learn and easy understanding.

- Patent injection wedge lifting mechanism, mechanical limit positioning mechanism, prevent accident happening.

- Patent filling pump symmetrical loading amount mechanism, ensuring the loading amount stability and material adaptation; design of reducing friction, prolong service life of this filling pump, reducing phenomenon happening of fill content too sticky caused by the heat over high temperature from friction, increasing product quality, less friction, it can increase main softgel machine rotary speed, increasing the encapsulation output.

- Patent mold cold air technology, it can increase production efficiency and output rate when encapsulate special content material

Introduction of SEC team, the first softgel service platform in China:

- SEC softgel encapsulation machine and softgel die roll tooling have been manufacturing since year 1986, by aerospace and military technology and as a founder of softgel industry standard in China, it’s the world leading technology.

- With over 50 softgel machine lines yearly, more than 60% domestic market and over 1000 sets yearly for softgel die roll set tooling, over 30 cases yearly of production improvement and technique training, we have customers over 50 countries in 6 continents, the typical overseas-known customers that available to say are like Sanofi, Amway, By-Health, TongRenTang, Angel yeast, Neptunus, Bright Future, PuraCap etc., currently the tapioca starch veggie softgel encapsulation can be stable 2.5RPM whole line & max 5RPM whole line on our standard 150x250mm softgel machine.

- SEC die roll sets are manufacturing for user’s all softgel machines in the world like from Korea, Japan, Canada, American, Italy, China and India etc., for end users directly but also OEM for other softgel machine suppliers, at the same time, spare easy damage parts are providing like lubrication oil roller, plunger, seals, heaters, gelatin hose, spreader box, drying cloth in tumbler dryer, drying trays different colours etc., We are doing repair and refurbish softgel encapsulation machines for end users which are originally manufactured from Korea, China, Canada etc., with finished softgel good sealing and die roll shaft vibration 3um.

- Under the years effort of our platform technicians and affiliated raw material manufacture site, now we are manufacturing and exporting SEC vegetable gelatin raw material, by composition tapioca starch, technical support for the guaranteed successful high quality and high output softgel production is providing globally for customers who buy the SEC vegetable gelatin material.

- 12-25

- 09-02

- 09-01

- 06-12

Address: No.1 Center Rd, Zhengxing St, Guan county south Development Zone, Langfang, Hebei, China

Address: No.1 Center Rd, Zhengxing St, Guan county south Development Zone, Langfang, Hebei, China

Email:

Email: