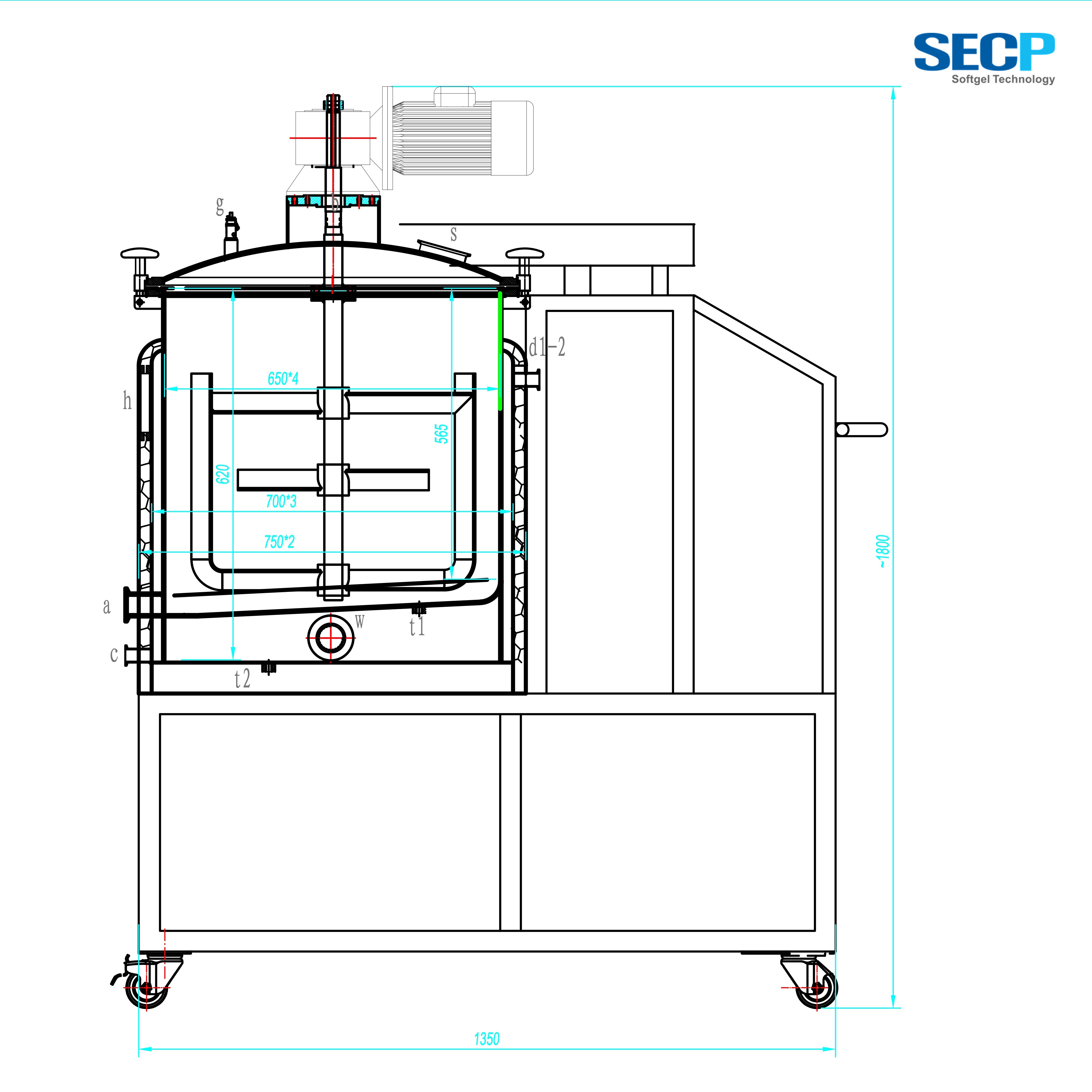

Veggie Gel Melt Feed One-Pot

Gelatin melting tank all in one pot system good for working of starch/carrageenan veggie gelatin and animal gelatin both, with functions of vacuum, mixing, melting/cooking, heat, insulation, lifting, protection, moveable, no need any auxiliary device to do the gelatin melting/cooking, available to start its operation only after the utility connected.

Recommended volume of this system for production batch need, and easier operation and moveable:

- 100L

- 200L

- 250L

- 300L

Stronger structure and different parameters when melting/cooking veggie starch gelatin.

Welcome to contact our professional sales engineer for further support at sec@secsoftgel.com

Three layers insulation heating structure by electric heating, it includes:

- water bath gelatin melting tank

- Integrated hydraulic lifting system

- Integrated vacuum condensing system

- Integrated gas water segregator

- Integrated water circulation vacuum pump

- Integrated electrical control box

- Heat insulation on both tank body and lid

- Vacuum protection system

Besides, there are jacket liquid inputting device convenient for user easy operating, jacket liquid reasonable discharge system etc.; the heat insulation on both tank and lid can help for the bottom gel mass maximum consumed to spreader box of softgel encapsulation machine for good softgel encapsulated as well, largely reduce the bottom gel mass wastage and increase the quality of softgel, the design and manufacture of its lid by heat insulation is the first and only one available on market now, its performance to reduce the bottom wastage during process of feeding spreader box can largely reduce the user production cost because of current much higher cost of animal gelatin material and high cost all the time for veggie gelatin material; There is not vacuum protection system for most of these integrated tank on market, its the SECP special design and support for user for this tank longer service life, avoid the damage on vacuum pump easily at start that often wrong operation.

The most durable and stable working system design and manufacture by SECP team, technology world leading and combine the actual softgel production demand based on the 35+ years accumulation and experiences, equipment is more praticable, easy operation and module type help for user quick knowing how to operate and work, clear the GMP requirements on each country/area for machine well comply with GMP, with rich knowledge and experience on each industry of softgel like medicine, supplement, paintball, cosmetic skin care, liquid for equipment performance always more than user's expect.

- 12-25

- 09-02

- 09-01

- 06-12

Address: No.1 Center Rd, Zhengxing St, Guan county south Development Zone, Langfang, Hebei, China

Address: No.1 Center Rd, Zhengxing St, Guan county south Development Zone, Langfang, Hebei, China

Email:

Email: