Design structure of starch vegetable softgel die roll, which is correct?

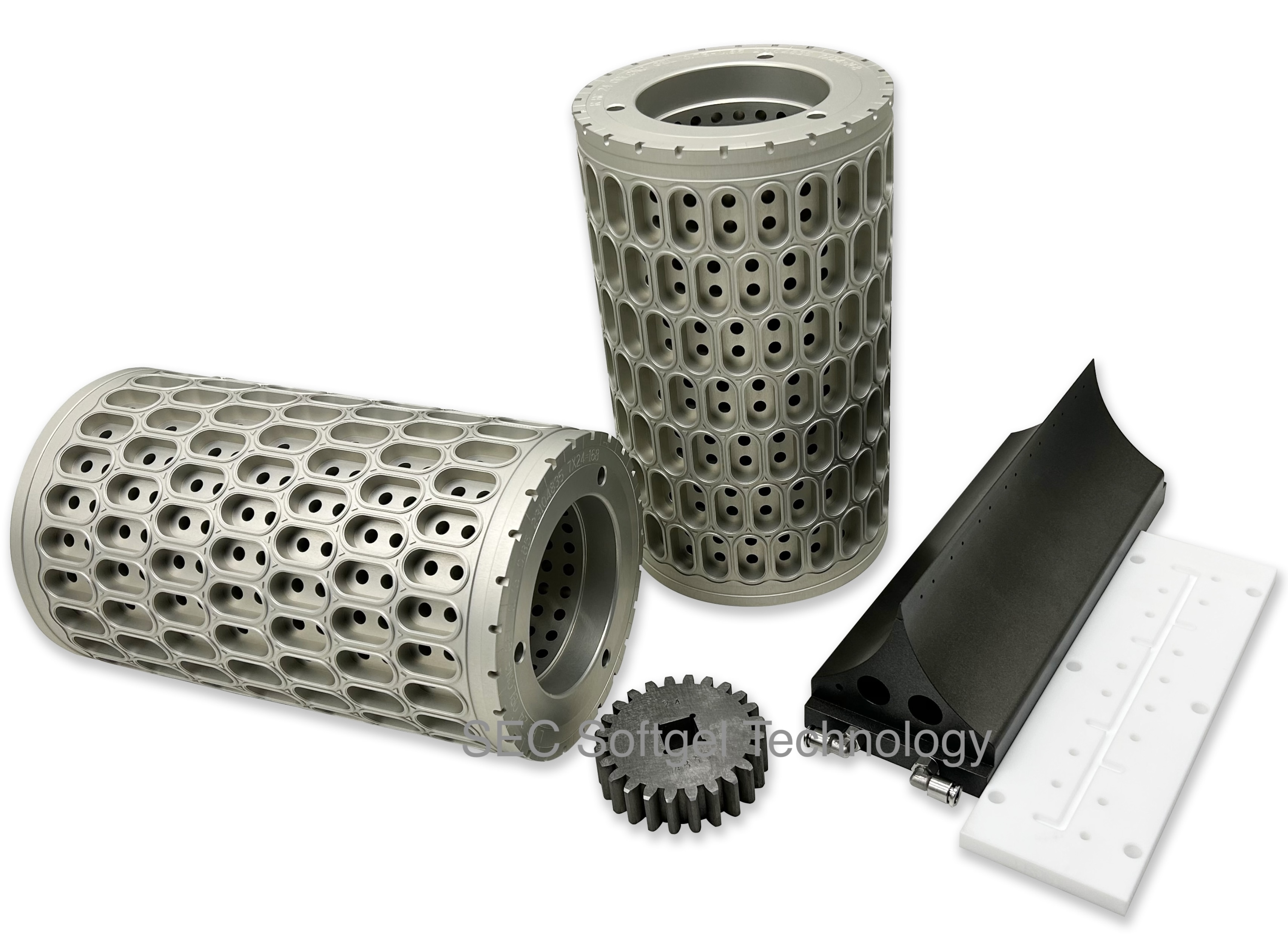

Softgel tooling die roll, its a small change part comparing with the softgel encapsulation machine, while its design and applicable structure requires almost all sides assembly of softgel machine knowledge and softgel manufacture technics knowledge. Its the heart and key to form correct shape size of softgel with expected quality.

In order to get the beautiful appearance softgel with straight both leading seal line and trailing seal line, correct softgel size and ratio, no leak, no break, no sticky etc., its definitely the basic capability to design and manufacture well of die roll for the SEC own manufactured softgel encapsulation machines, machine structure information and its working conditions and its machine principle are also required when design and manufacture die roll for the world others softgel machine manufacturers typical examples like Bochang, Technophar, GIC, Kamata,Cube, IRE, SKY, Changsung, Tooltronics, Sinagel, Pharmagel, also brands like saintyCo, Jangli, Hedagel...along the manufacture around 1000 die roll sets annually and the long experience years, its one of the most advantage of SEC, we appreciate that user feedback us the best designer and world biggest manufacturer of die roll.

Design structure of starch vegetable softgel die roll, it can be simply said, max seal and triple step is correct, lets go for its summary:

- Cavity size design

Suitable cavity size shall be considered not only from feature of fill material, on starch vegeteable shell, its more important to know the correct shrinkage rate from wet softgel to dried softgel which is during the drying process. SEC knows well the shrinkage rate for almost all the various types starch vegetable gelatin material, from our own R&D and also from our team members who are also working in softgel manufacturer, it helps to update the data base almost every day.

Welcome to contact SEC professional sales engineer for further technical communication at sec@secsoftgel.com

- Triple step design

Triple step is well known by most softgel manufacturers and professionals, while same called triple step from each manufacturer, they would be completely different. It varies from each step width and length, and requires correct consideration of their each other relationship during encapsulation.

Vegetable gelatin is sealed physically and different with animal gelatin, correct triple step can help to fix the gelatin ribbon well at the moment of sealing.

- Max seal design

Max seal works on the most seal rate for animal suspension / viscous fill mixture and starch vegetable etc., like high concentration krill oil astaxanthin, chinese herbal medicine mixture, paintball with PEG mixed fill etc.,

when on animal gelatin, max seal provides good help on one more typical case which is the EC gelatin, enteric coated for time release, its the strongest seal and the results help produced softgel 100% pass on gastro test.

Combine max seal on triple step, with each parameters correct considered, its results on any starch vegetable gelatin are amazing and the most exciting.

- Chamfer size design

- Concentricity and verticality precision manufacture

Manufacture precision of die roll is mainly on the concentricity and verticality, besides pricesion, it helps the more durable die roll, longer service life.

- Bead blasting surface treatment manufacture

Bead blasting is a surface treatment step, different with others, SEC do the bead blasting process by full automatic machine which is customized developed on this process by SEC self, it guarantees the evenly and full treating. This treatment has no any disadvantage on softgel manufacturing, instead, it helps the more seal thickness, and only works for more seal thickness.

Commit to reducing cost and increasing production efficiency for softgel manufacturers, SEC dedicate ourselves continuous innovation and research for simpler and easier production of softgel.

- 12-25

- 09-02

- 09-01

- 06-12

Address: No.1 Center Rd, Zhengxing St, Guan county south Development Zone, Langfang, Hebei, China

Address: No.1 Center Rd, Zhengxing St, Guan county south Development Zone, Langfang, Hebei, China

Email:

Email: